13/08/2018 / News

EVI, BOOM and T.I.C.K

Three pillars ensure continuous improvement

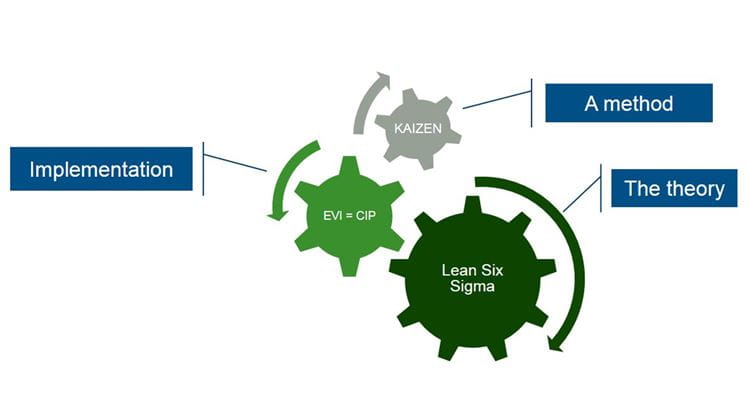

The structured CIP has already been firmly established at Ensinger for nine years. Over the years it has been consistently further developed and adjusted. The programme is referred to as the Ensinger improvement tool (EVI for short) and is based on three pillars:

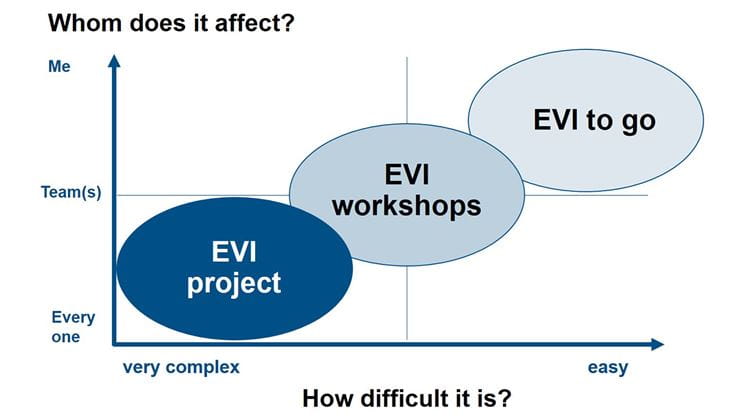

1. Operational EVI with small improvements (KAIZEN) by means of simple methods and measures which the employees can use straight away and, in the process, help make each day a little better (EVI to Go). When it gets more complex, chaired EVI workshops support the teams. Specially trained facilitators exist for this purpose. Overarching and more long-term topics are approached with the aid of improvement projects. Here, the Lean Six Sigma Method is used. When it comes to finding solutions, the internal CIP team advises the divisions and agrees on the measures.

2. Training and development are the basis for the improvement culture. All employees will be given appropriate training over the next few years to be able to get to know and use the EVI methods. For the purposes of professional development there is expert training available such as sessions for facilitators or the Lean Six Sigma Green Belt.

3. An effectiveness test makes improvements measurable with the aim of thereby highlighting the benefit and success of a measure to everyone. These are not just measured in terms of monetary value but also using a points system. Because lots of improvements cannot be expressed in euros.

Focusing on employee collaboration

At our US subsidiary Ensinger Inc. a similar CIP tool has been running since 2012 under the name BOOM. There, the improvement motto is “Believe, Our Opinions Matter”.

When EVI met BOOM in Washington, PA, the local facilitators got a further insight into Lean techniques and the “8 types of waste”. Extremely motivated, they also immediately carried out a Lean 5S workshop in the Production department.

When EVI met BOOM in Washington, PA, the local facilitators got a further insight into Lean techniques and the “8 types of waste”. Extremely motivated, they also immediately carried out a Lean 5S workshop in the Production department.

At the headquarters of the British subsidiary Ensinger Ltd. the programme T.I.C.K. was recently introduced; this is also based on EVI. T.I.C.K. stands for “Team Interaction Creates Kaizen”, in other words it is also intended to identify and implement improvements through the participation and collaboration of employees.

The international sites are, with their methods, guided by the local requirements and possibilities, but all Ensinger CIP strategies have one thing in common: They all make use of employee initiative and team spirit.