2017-05-31 / Press Release

insulbar by Ensinger: Framing buildings with future

Demand for thermally insulated metal frames continues to rise, says Metal Yapi, one of the world’s leading facade specialists

Thermal break

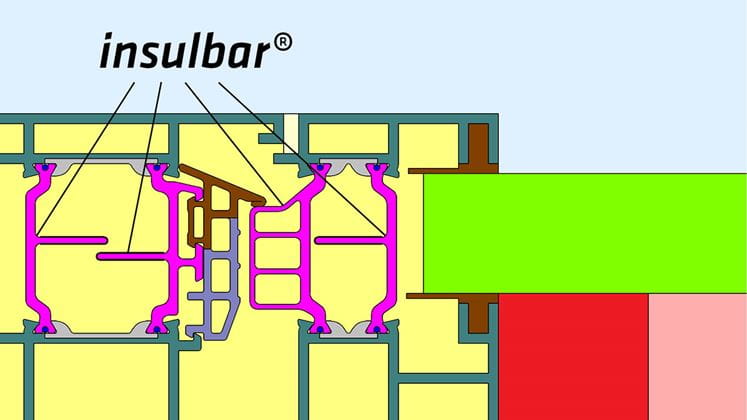

Metal Yapi develops innovative facade systems for reputable objects all over the world. Aluminum is thereby most commonly employed. Its structural strength allows for light and slim frame designs. Yet, the metal’s high thermal conductivity needs to be compensated. “Our metal frames consist of an inner and an outer shell, stably interconnected by an insulating profile such as insulbar from Ensinger”, Biler explains. “Its material and design allows for creating energy preserving metal frames – even for passive houses.”

German plastic specialist Wilfried Ensinger was the first to produce highly insulating profiles for metal framing systems back in 1977 and in doing so revolutionized the fenestration industry. “Continuously further developed, these profiles are available today in a broad range of materials and designs for standard to special purposes”, knows Oguz Han Erol, Application Specialist at Ensinger’s office in Istanbul. “By optimizing the thermal separation of metal windows, doors and facades, ‘insulbar’ has become a quality hallmark around the world.”

Customized standards

The basic material for insulbar is TECATHERM 66, a glass fiber reinforced polyamide (PA). Highly insulating, stable and yet elastic, it provides superior mechanical properties and durably resists every climate and weather. Its coefficient of linear thermal expansion is similar to metal, resulting in minimum material stress during temperature shifts. This also applies to the RE version made of pure recycled PA or the recently presented lambda-optimized ‘insulbar LO’ with a thermal conductivity (λ) of only 0.18 W/m·K.

All profiles can be equipped with flags, coated with low-E-film (LEF), to reduce loss of heat even more effectively. insulbar is flame resistant (classification E acc. to EN 13501-1, B2 acc. to DIN 4102) and withstands temperatures of up to 200 °C for 20 minutes. For metal processors, this has the advantage that the insulating bar can be rolled into the framing shells before anodizing or powder coating. This enables minimized internal variance, efficient processing and a large color variety at the end of the value-added chain.

Making the difference

“We support the fenestration industry with comprehensive services in configuring the optimum profile: with an easy-to-use app on our website as well as personal expertise in application engineering”, says Oguz Han Erol from Ensinger. “In the development phase, we provide competent advice from the project-specific choice of material and geometry, energetic calculation and design to rapid prototyping. And we continue by ensuring the highest quality in processing, handling and logistics, up to the application of the insulating profiles."

"Along with the quality, variability and innovation of the product, these services make the difference for us," says Biler of Metal Yapi. "Project specifications vary and are often challenging. Since we have set ourselves the ambitious goal of becoming the best facade company in the world by the year 2023, we rely on outstanding partners. This particularly applies to our efforts to further increase the energy efficiency of our solutions, as the building envelope has a lasting effect on the comfort and cost-effectiveness of an object.”

Reducing energy loss

Other than the translucent glazing, which can generate energy gains, the frame is part of the opaque building envelope. To reduce energy losses to a minimum, the frame portion of the window box-out, which can vary from over 20 percent to below 10 percent, should be as small as possible. This can best be achieved by using metal with a highly efficient thermal break. For Metal Yapi’s projects in Turkey, the expected overall thermal transmittance value for a window or a curtain wall is often 1.5 W/m2K or below.“Although the building code TS 825 currently requires an Uw of only 2.4 W/m2K, investors want to further reduce energy consumption in their buildings”, he says. “Not only for the eco-image, but also to remain more independent from potentially rising energy costs – in energy importing countries such as Turkey this is an important factor because the buildings are used for decades.” One example is the Orjin Maslak, a 16-story office center in Istanbul. Its aluminum-framed double facade achieves an Uw of 1.26 W/m2K. It was one of the first buildings in Turkey to be awarded a LEED Gold rating in April 2015.

Building the future

Metal Yapi is equipping a growing number of prestigious buildings with thermally insulated facade systems, currently reaching Uw values down to 1.2 W/m2K in Turkey. While the Mediterranean climate is rather mild, the demand for even lower U-values increases in colder climates. Using insulbar by Ensinger, Metal Yapi even achieves passive house standards according to PHPP, e.g. at “The One” (Uw of 0.90 W/m2K) and the “Belliard 40” (Uw of 0.75 W/m2K) in Brussels, Belgium.

About insulbar

Ensinger GmbH is among the world's leading developers and producers of insulating profiles for window, door and facade construction. The profiles marketed under the brand name insulbar create a thermal separation between the inside and outside shells of metal frames. Insulation systems using insulbar profiles achieve optimum values in terms of energy savings and cutting the cost of heating and cooling. At the same time, insulbar profiles comply with the most stringent quality standards in every respect. They have been in successful operation around the world for over 40 years.

For more information, go to www.insulbar.com

About Ensinger

The Ensinger group is engaged in the development, manufacture and sale of compounds, semi-finished materials, profiles and technical parts made of engineering and high performance plastics through extrusion, machining and injection molding. With a total of 2,300 employees at 32 locations, the family-owned enterprise is represented worldwide in all major industrial regions with manufacturing facilities or sales offices.

For more information, go to www.ensingerplastics.com

Press Contact and Additional Information

Karin Skrodzki

Ensinger GmbHPR and Communication Building Products

Rudolf-Diesel-Straße 8

71154 Nufringen

Germany

Phone +49 7032 819 674

[obfemailstart]a2FyaW4uc2tyb2R6a2lAZW5zaW5nZXJwbGFzdGljcy5jb20=[obfemailend]