24/09/2018 / News

Shear-free: the insulating profile for doors

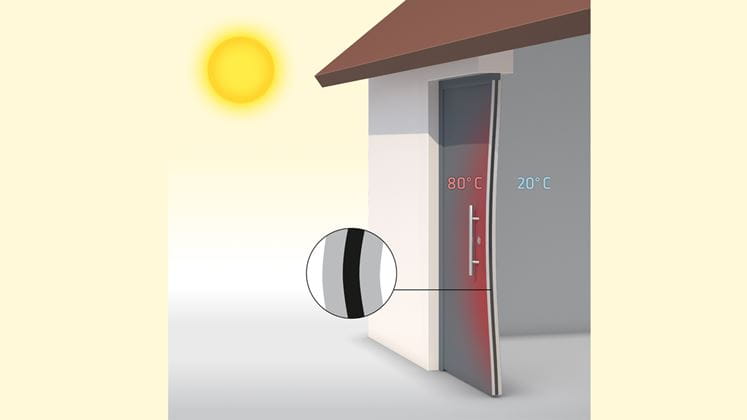

Ensinger has a new solution to the well-known problem encountered with thermally separated metal doors, the bi-temperature effect (also known as the bi-metal effect). Above all in front doors situated on the sunny side of the building, the outer aluminium shell expands significantly when it heats up. As a result of the temperature difference between this and the inner shell, the entire assembly bulges outwards. The door becomes deformed and, at worst, can no longer be opened or closed. This effect is amplified when the door is painted in a dark colour, as the surface gets particularly hot.

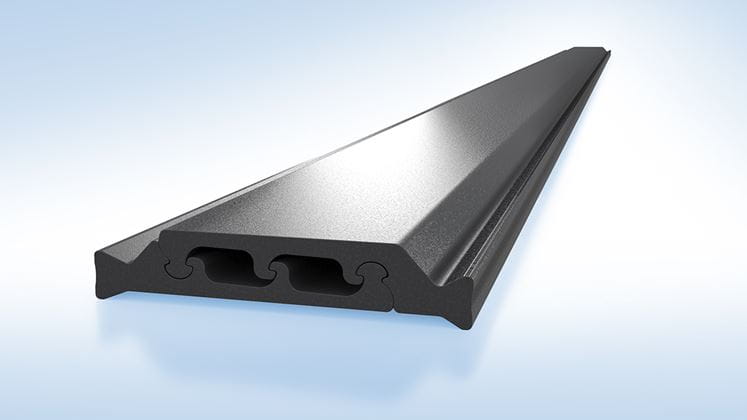

The new shear-free bar consists of two parts.

The new shear-free bar consists of two parts.

A high insulation depth also makes the differing linear expansion more likely, because the difference in temperature between the outer and inner sides of the door is even greater here. This symptom can also occur in winter, but in this case, when it is very cold outside and warm inside, the door bends inwards.

Aluminium assembly with normal insulating profile: the large temperature difference causes the door to become deformed.

Aluminium assembly with normal insulating profile: the large temperature difference causes the door to become deformed.

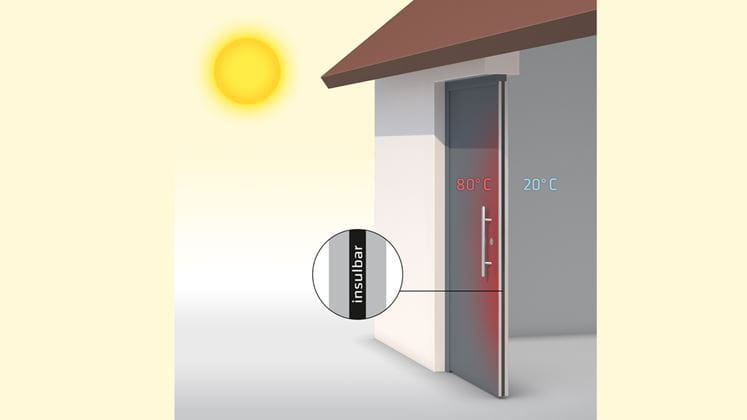

Aluminium assembly with shear-free insulbar insulating profile: the flexible insulation zone evens out the differing linear expansion between the inner and outer shells effectively.

Aluminium assembly with shear-free insulbar insulating profile: the flexible insulation zone evens out the differing linear expansion between the inner and outer shells effectively.

Solution with patent pending

With the shear-free insulbar insulating profiles, this is a thing of the past. The shear-free bar consists of two parts which, in the event of differing linear expansion between the inner and outer shell, shift against each other. A flexible insulation zone is generated which evens out the differing thermal expansion properties of the aluminium shells and minimises the bi-temperature effect.

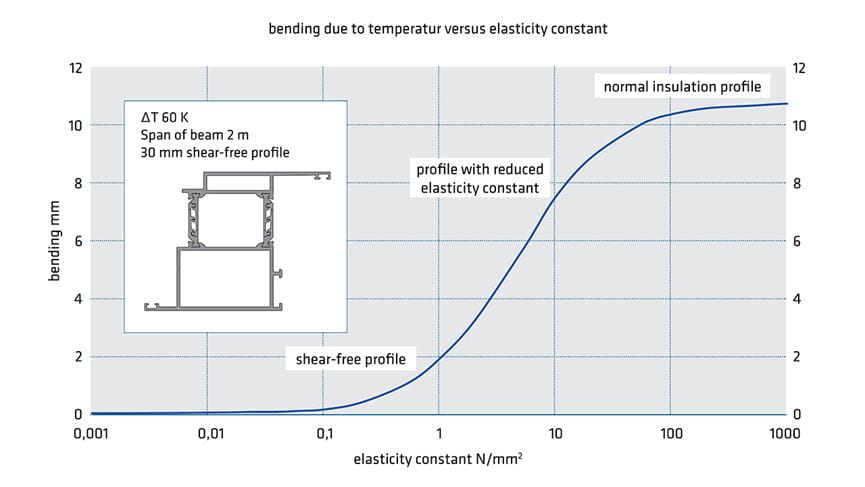

The shear rigidity c of the shear-free insulbar insulating bar is almost zero. Bending of the door is thus significantly minimised (see diagram).

The shear rigidity c of the shear-free insulbar insulating bar is almost zero. Bending of the door is thus significantly minimised (see diagram).

All the benefits at a glance

- Shear-free, consequently a more significance minimisation of the bi-temperature effect compared to shear-weak and shear-resistant profiles

- Minimal shear rigidity c and low shear strength T

- Optimised geometry for high transverse tensile strength Q

- Can be rolled up and laminated like a conventional insulating profile

You can already find the shear-free profile in a variety of sizes between 20 and 42 mm in our standard range and in the insulbar Finder under the section Special applications.

We are happy to support you with developing your new product and can provide you with relevant samples. Talk to us.