22/05/2019 / News

It’s all about the frame:

This is how the insulation zone is optimised

From outside, the efficient thermal separation and thermal insulation of aluminium windows is barely visible; nevertheless it is a key factor in a comfortable and energy-saving living environment. Through the linking of the outer and inner shells of the metal system by means of insulbar insulating bars, an insulation zone is generated in the interior of this frame assembly. When creating this zone, the design engineer has a variety of options available for optimising the thermal insulation and bringing about a desired Uf value using construction measures. The different types of heat transfer are crucial here.

The 3 types of heat transfer

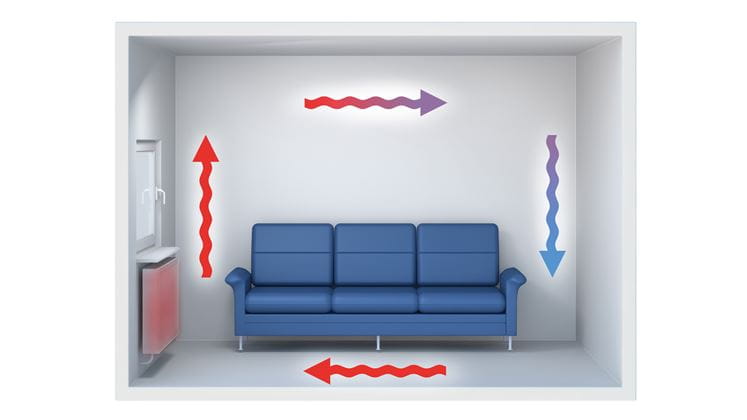

Heat is energy which, by means of thermal conduction (transmission), heat convection and radiation (emission), always flows towards where the temperature is lower.

Optimisation of the insulation zone

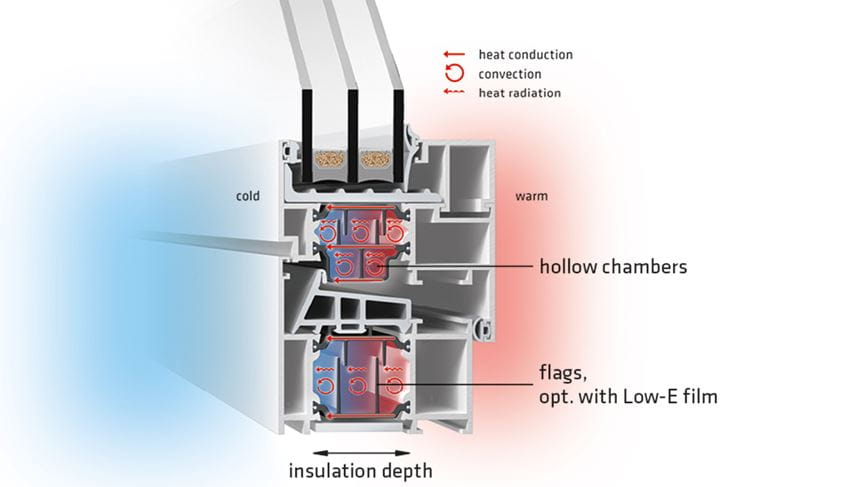

For efficient insulation tailored to the particular requirements, it is necessary to combine and finely tune several individual influencing variables in the insulation zone. Here it is above all the individual types of heat transfer that form the starting point (see Figure):

• In order to minimise thermal conduction, materials with a low thermal conduction capacity and high strength are used, for example materials made from glass fibre reinforced polyamide 66.

• The reduction of wall thicknesses and increase in insulation depths of these insulating profiles are further possibilities for keeping the heat transfer through transmission at a low level.

• A reduction in the size of the cavities within the insulation zone minimises the air circulation, i.e. the convection. Insulating profiles with hollow chambers or profiles with inwardly directed flags generate smaller convection cells of this type.

• A very effective method is the use of bars with flags to which a thin Low-E film is applied. This aluminium film ensures a high level of reflection of the heat radiation and works in a similar way to the Thermos flask principle.

Step by step to the desired Uf value

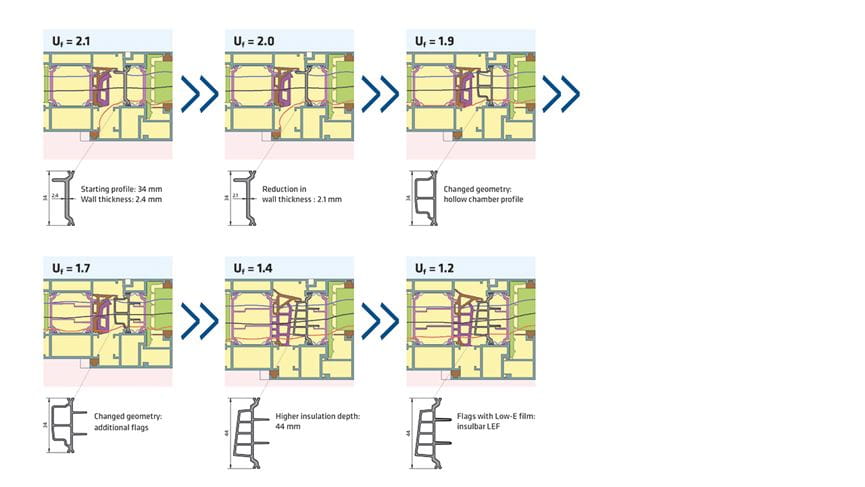

The figure below shows by means of sample cross sections how, using the above-named measures and with the aid of insulbar insulating profiles from Ensinger, the Uf value can be optimised step by step in heat technology terms. By changing the individual parameters, the thermal transmission coefficient is minimised down to the desired target value.

Step by step to the desired Uf value: By changing the individual parameters, the thermal transmission coefficient is minimised down to the desired target value.

Step by step to the desired Uf value: By changing the individual parameters, the thermal transmission coefficient is minimised down to the desired target value.

Summary: A winning combination!

When aiming to thermally separate aluminium frames in an efficient manner, the developer has lots of options but must combine the various individual adjustable parameters. This is because there are functional and mechanical limits to thermal optimisation using just one influencing factor. For example, certain minimum wall thicknesses are required to ensure the required strength of the insulating profile. A specified budget may have a limiting effect on the design of the insulation zone. If, however, the named influencing variables are carefully tailored to each other, then in combination the optimum thermal insulation and the desired Uf value can be achieved for the relevant visible width. In this way valuable energy savings can be made and simultaneously the living comfort be significantly improved.

If you would like to know more about the possibilities for optimising thermal separation then we would be pleased to hear from you! Our experts from Application Engineering will be delighted to show you the options.