insulbar RE – The sustainable insulating bar made of 100 % recycled polyamide

Our contribution to responsible sustainability

INSULATING BARS FOR MINIMAL ENVIRONMENTAL IMPACT AND OPTIMUM SUSTAINABILITY

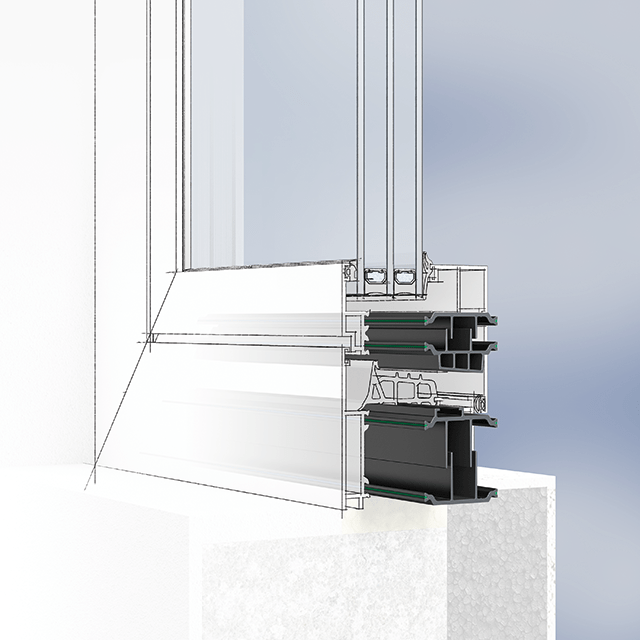

insulbar RE is made of 100 % recycled polyamide, and so saves precious energy and precious resources right from the manufacturing stage. Compared to conventional polyamide bars, the consumption of fossil fuels is reduced by 92 %, carbon emissions are cut by 91 % and water consumption by 78 % – as conformed by the EPD (Environmental Product Declaration). When assembled, the profile provides impressive thermal separation, enables excellent Uf values and so reduces energy consumption and heating costs. You can achieve even better Uf values with insulbar RE-LI.

The outstanding ecological balance of insulbar RE is already apparent at the manufacturing stage. Here it is shown in comparison with a conventional insulating profile from non-recycled polyamide.

The outstanding ecological balance of insulbar RE is already apparent at the manufacturing stage. Here it is shown in comparison with a conventional insulating profile from non-recycled polyamide.

RELIABLE FUNCTION IN THE LONG TERM

insulbar RE provides outstanding mechanical properties and is also identical in terms of its durability and functional reliable to conventional insulbar REG insulating profiles. This gives you the opportunity to convert your systems from REG to sustainable RE without major expenditure, thereby improving their eco-balance or carbon footprint.

By using high-quality recycled polyamide, the material properties are comparable to those of virgin material. In this way, continuous quality surveillance and suitability testing of the plastic in compliance with DIN EN 14024 ensures (raus guarantee) optimum quality since 2013. The profile is available in standard designs or produced to individual customer order.

ADVANTAGES AT A GLANCE

Sustainable

- Made of 100 % unmixed recycled polyamide

- Optimized for environmental protection and sustainability

- Ideal for "green" construction/building certifications

- Rapidly improves the environmental performance of existing systems

- Consumption of fossil fuels: - 92 %

- Carbon emissions: - 91 %

- Water absorption: - 78 %

Certificated

- Complete with environmental declaration: EPD to DIN ISO 14025 and EN 15804

- Cradle to Cradle Material Health Certificate

- Consistently high standard of tested quality

Functional

- Excellent insulating effect

- Durable and functionally reliable

Downloads

For more information about insulbar RE recycled profiles, see our brochure, the EPD (Environmental Product Declaration) or the Cradle to Cradle Material Health Certificate.