Perfect coating and improved appearance

insulbar with ESPOC

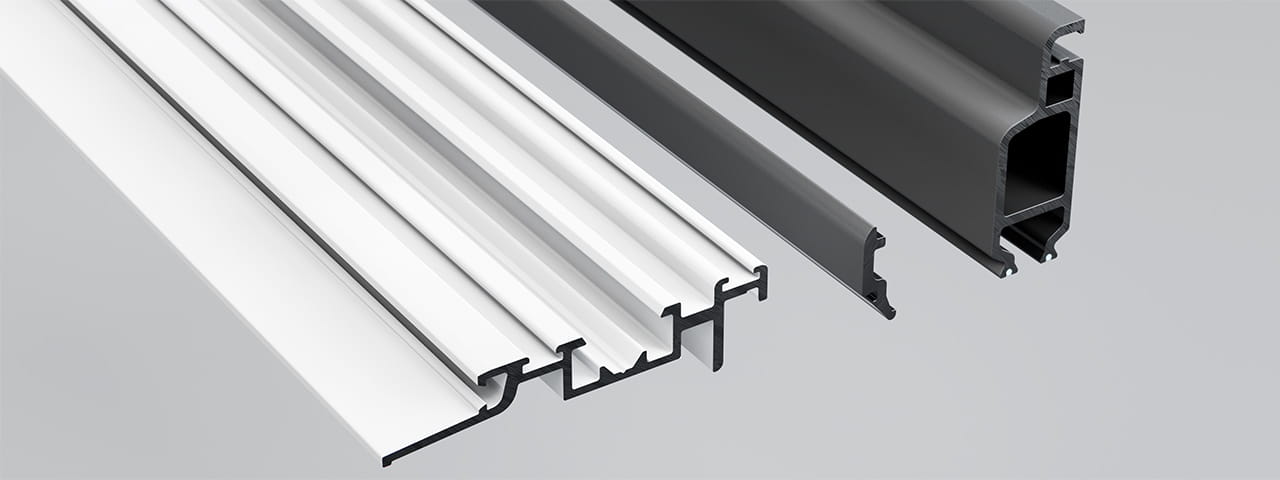

With ESPOC, Ensinger has developed an innovative solution that opens up new design possibilities for window and door systems. ESPOC is an extremely thin coating that is applied to our standard profiles or to customer-specific profile designs using a special process.

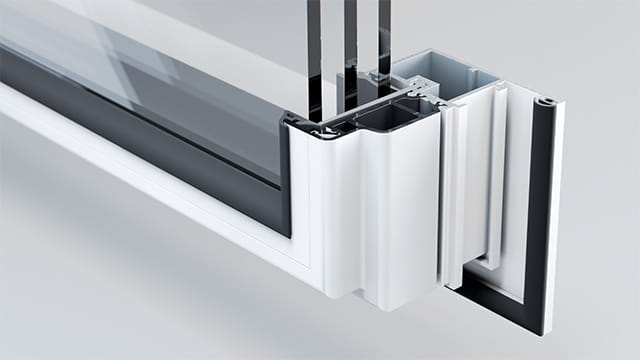

Even on the most challenging insulbar profiles with multiple visible sides, protrusions and undercuts, our innovation enables a virtually perfect powder coating of our customers' systems.

In combination with our insulbar REG, insulbar RE, insulbar LI and insulbar RE-LI products, this results in high-quality, highly insulating and sustainable window and door systems – for maximum design freedom and the highest quality.

Would you like to find out more?

Our ESPOC team will be happy to advise you.

What is the ESPOC effect?

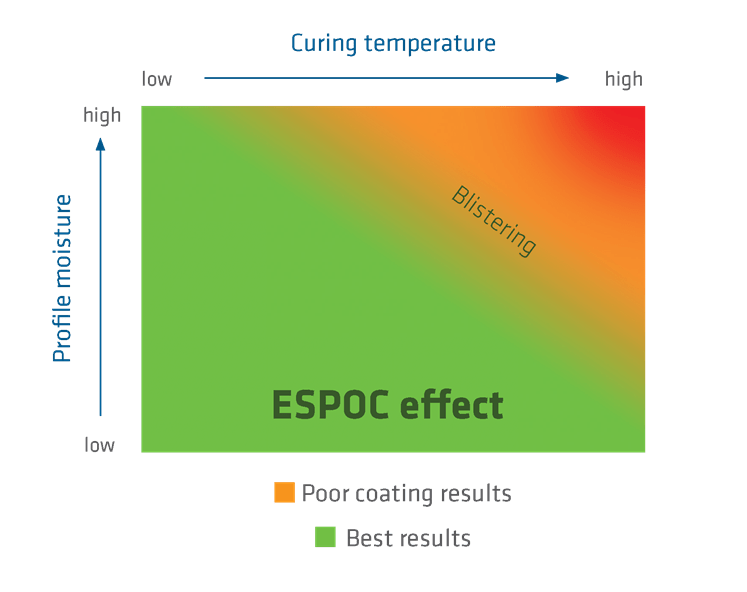

The ESPOC effect works by attracting powder exceptionally well – especially on dry insulbar profiles.

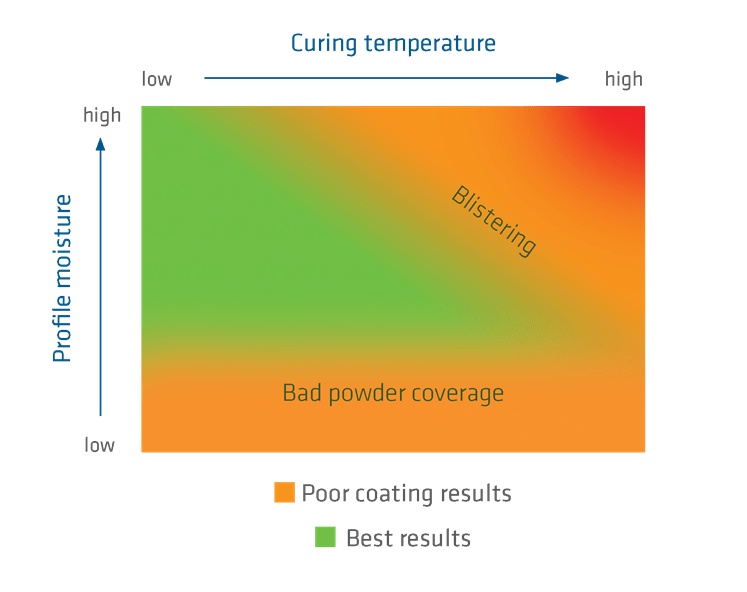

Without ESPOC coating

With ESPOC effect

How does pre-drying the profiles help to improve your process?

Moisture content over time*

* Please note: Illustration for principal explanation

* Please note: Illustration for principal explanation

To avoid this and achieve a perfect powder coating result, we recommend using dry or pre-dried insulbar profiles.

ADVANTAGES AT A GLANCE

Optics

- High-quality appearance in the profile system

- Perfect coating result possible

Flexibility

- Applicable to existing or new standard and customised profiles

- Can be applied to many insulbar materials

- Available as an option

Process improvement

- Safer and improved powder coating process

- Lower reject rate

- Improved paint adhesion

- High attraction in the powder coating process in assembled or solitary profiles

Further advantages

- New and greater degrees of freedom in the design of visible insulating profiles

- Unchanged thermal conductivity of the base profile

- Consistent mechanical properties

HOW DOES IT WORK?

Downloads

Further information on insulbar with ESPOC can be downloaded here.